| To | Mohamed Misbah |

| Tuam txhab | Forsan Foods & Consumer Products Co., Ltd |

| Lub teb chaws | Saudi Arabia |

| Cov ntaub ntawv NO. | LY-20200529001BY |

| Hnub tim | 20200529 |

Aluminium Can Carbonated Dej Haus Filling Ntau Lawm Kab

Muaj peev xwm 2000BPH (320ml)

(PROPOSAL DETAILS)

Hu rau: Bobby Liu

Xov tooj / whatsapp: +8613773224489

E-mail: bobby@lymachinery.com

Cov lus pom zoo no yog ua ntej, ua raws li kev pom zoo kawg tom qab kev sib txuas lus kev lag luam thiab kev lag luam.Lub sijhawm siv tau: 3 lub hlis.

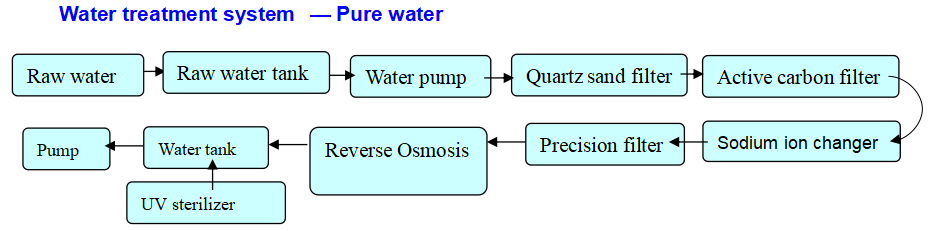

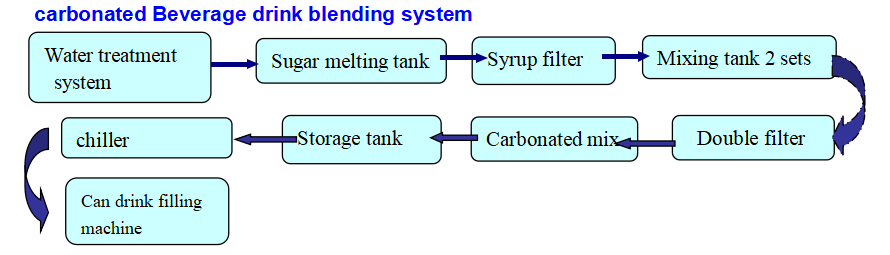

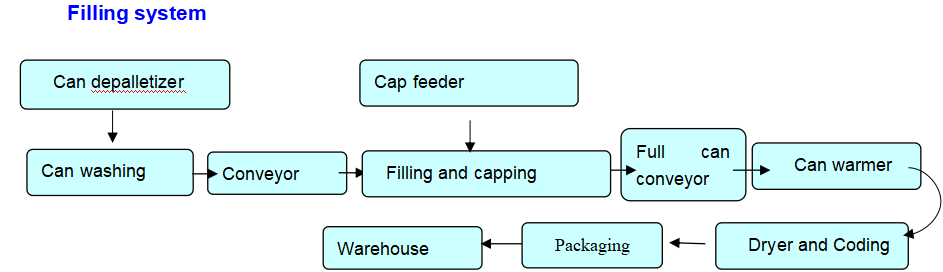

Flow Chart

Ⅰ, Cov Khoom Siv & Cov Ntawv Sau Nqi

Ⅱ, MACHINE DESCRIPTION

1.Carbonated Drink- Blending & Mixing system

A) Cua txias lub thawv hom chiller

QHS2000 series haus tov khoom qauv tsim nyog, qhov sib tov precision siab, CO2 sib tov tag nrho, muaj ob lub sij hawm ntawm txias, ob carbonation zoo. Feem ntau yog tsim rau hom carbonic acid haus cov kev sib xyaw ua ke, kuj tuaj yeem siv rau hauv cov dej haus muab tshuaj, dej haus fermentation thiab lwm yam dej qab zib 'kev sib xyaw ua haujlwm.

B) CHARACTERISTIC

1. Cov ntaub ntawv zoo heev, kev ua haujlwm yog qhov tseeb:

Txhua tus xaiv cov khoom lag luam zoo stainless hlau nrog rau qhov chaw haus dej haus, sab hauv, sab nrauv dhau los ntawm kev ua polishing tiav, ua tiav raws li cov khoom noj thoob ntiaj teb.

2. Automaticity siab, lub zog ruaj khov:

Lub tshuab no los ntawm microcomputer tswj kev tsim khoom lag luam tag nrho cov txheej txheem, lub zog ruaj khov; Yog tias tawg, lub tswb nrov tuaj yeem ua kom sai thiab automatism nres.

3. Qhov yooj yim ntawm kev ua haujlwm, yooj yim kho:

Lub tshuab ua haujlwm no yog pib khawm nyob rau hauv lem raws li tus txheej txheem teev tseg, ces realizes cov hauj lwm ib txwm; Tsis tas yuav hloov cov khoom seem, uas tuaj yeem yooj yim kho cov khoom tsim tau lossis sib xyaw ua ke ntawm cov dej thiab qab zib.

4. Sib tov sib npaug, qhov kev faib ua feem yog qhov tseeb:

Vim tias siv cov khoom siv pov tseg pov tseg cov khoom siv tes ua siab heev, yog li kev sib xyaw yog txawm; Kev faib ua feem ntawm cov dej thiab cov syrup sib tov yog tswj los ntawm qhov zoo tuning muaj nuj nqi ntsuas kev txhim kho nruj me ntsis, nws mix precision yuav ncav cuag li 5/1000

5. Cov ntsiab lus CO2 siab:

Lub tshuab no siv lub tshuab nqus tsev deaeration, tus nqi deaeration nce mus txog siab tshaj 90%; Muaj qhov deaeration, carbonized ob lub cua txias ua haujlwm, muaj cov haujlwm uas ob lub sij hawm carbonizes, Yog li cov ntsiab lus huab cua tshwj xeeb yog siab, feem ntau yuav ua tiav 3.5 ~ 3.8 lub sijhawm lossis siab dua me ntsis.

6. Cov qauv kev noj qab haus huv, yooj yim los ntxuav:

Lub tshuab no siv lub voj voog uas cov hlau tsis muaj hlau ua, tau txaus siab rau CIP lub tsev purifier nqa mus rau cov khoom siv thiab cov raj xa dej ploj cov venom thiab cov dej kub huv huv; Lub tshuab no ntau lawm haus, txhua milliliter cov kab mob tsim tawm tus nqi<5%, Escherichia coli yog xoom.

C) Kev kub ceev melting tank

Stainless hlau SUS304, sab hauv zais zis δ3mm, mais board yog δ1.5mm, sab nraud stainless hlau board yog δ1.5mm, thiab polyamine npuas rwb thaiv tsev, tiav kaw, ntsug syrup stirring, 60r / min, digital ntsuas kub, lub cev muaj zog yog 1.1KW. Ntxuav lub taub hau 、 cov khoom siv hluav taws xob hauv qab yog Ф38 thiab ua pa.

E) Dej Pump

Kev sib cuag nrog cov ntaub ntawv, twj tso kua mis vaj tse, impeller, txiv ntseej thiab kev txhawb nqa ko taw yog ua los ntawm stainless hlau 304 cov khoom, thiab lub nplhaib sealing yog ua los ntawm cov khoom noj huv si roj hmab thiab lub nplhaib sib khi nyuaj.

D) Hnab hom Duplex Lim

Ua los ntawm stainless hlau 304, ob chav sib npaug qauv, nrog 100 mesh stainless hlau mesh sab hauv, lub vijtsam lim tuaj yeem hloov tsis tau kaw.

F) Dej Pump

Kev sib cuag nrog cov ntaub ntawv, twj tso kua mis vaj tse, impeller, txiv ntseej thiab kev txhawb nqa ko taw yog ua los ntawm stainless hlau 304 cov khoom, thiab lub nplhaib sealing yog ua los ntawm cov khoom noj huv si roj hmab thiab lub nplhaib sib khi nyuaj.

G) CIP system

Lub tank lub cev yog ua los ntawm SUS304. Lub thickness yog 3 hli. Cov kua qaub thiab alkali tso tsheb hlau luam yog muab nrog txheej rwb thaiv tsev.

Sab hauv thiab sab nraud welds ntawm lub tank lub cev yuav tsum tau polished. Tsis muaj lub kaum sab xis tuag hauv lub tank kom yooj yim tu.

Lub tank lub cev yog nruab nrog lub khob kua ntsuas ntsuas, lub tshuab nqus plua plav pov thawj, lub tshuab nqus dej, lub qhov hluav taws xob ua kua, lub qhov hluav taws xob ntws, lub ntsuas ntsuas, lub tshuab nqus tsev ceev ceev, thiab lwm yam.

Adjustable theem ntawm ob txhais ceg.

2. Aluminium Can Carbonated Dej muab tub lim & ntim khoom

A) Empty cov kaus poom depalletizer

Pop tuaj yeem khoob tuaj yeem depalletizer yog qhov tsim nyog rau tsis siv neeg depalletizing ntawm tag nrho pawg ntawm cov kaus poom khoob. Nws hoists lub khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob. Siv ua ke nrog cov khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob

Thaum lub sijhawm ua haujlwm, lub forklift muab cov pallets uas cov kaus poom tsis muaj palletized mus rau lub pallet conveyor, thiab cov conveyor yuav nqa mus rau lub pallet nqa platform ntawm lub tshuab loj. Lub pallet nqa platform yog siv los xa cov ntim khoob khoob rau hauv qhov siab tuaj yeem tshem tawm. Thaum cov kaus poom khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob. Tag nrho cov nce thiab poob nqis yog tswj los ntawm tus kheej-locking lifting system ntaus ntawv. Qhov nce lossis poob nrawm tuaj yeem hloov kho kom tau raws li qhov xav tau ntawm kev ua haujlwm. Thaum lub sijhawm khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob lwm pawg. Txhua qhov kev nqis tes ua yog tswj los ntawm photoelectric hloov. Lub peev xwm unloading nrog tas mus li kev ua los yog ib hom circulating tuaj yeem xaiv tau.

Lub pallet pub kev taw qhia, tuaj yeem tso tawm cov kev taw qhia thiab kev ua haujlwm vaj huam sib luag txoj haujlwm ntawm lub tshuab tuaj yeem hloov pauv tau raws li cov neeg siv khoom xav tau.

Main technical parameters:

Muaj peev xwm ntau lawm: 30 ~ 400can ib min

Lub Zog: 3.5kw

Qhov hnyav: 2500kg

Loj: 7000 * 4500 * 3500mm

B) Slideway tuaj yeem ntxhua khaub ncaws

Pem hauv ntej tuaj yeem tig- dhau lub tawb txiav ntawm lub tshuab ntxhua khaub ncaws yog txuas nrog kev thauj mus los sai ntawm lub peev xwm thauj khoom tig-rooj. Cov kaus poom khoob uas tuaj ntawm lub tshuab tig-dhau muaj 180 ° tig. Tom qab ntawd tus tuaj yeem nkag mus rau hauv lub tank ntxhua khaub ncaws ntawm qhov khoob tuaj yeem ntxuav los ntawm qhov qhib downward. Hauv qab ntawm lub tank yog qhov dej ntws. Cov dej uas txau rau hauv qhov khoob tuaj yeem ntws rov qab rau hauv lub tank, ces cov dej khib nyiab tawm los ntawm cov kav dej tawm. Tom qab ntxuav qhov khoob tuaj yeem muaj 180 ° tig los ntawm lub nraub qaum tuaj yeem tig-tshaj tshuab, tom qab ntawd tus tuaj yeem nkag mus rau cov khoom siv conveyor siv los ntawm kev qhib upward.

Main technical parameters:

Muaj peev xwm ntau lawm: 30 ~ 400can ib min

Luj: 150kg

Loj: 4000 * 500 * 2300mm

C) Tau Filler / Sealer

Lub monoblock yog tsim:

FILLER-SEALER

Kev Taw Qhia General:

Nws yog tsim rau sau thiab capping carbonated dej haus xws li cola, carbonated dej thiab lwm yam. Nws yog txawm peem rau nrog advanced ntaus ntawv, hluav taws xob khoom, thiab pneumatic tswj tshuab. Nws muaj cov yam ntxwv ntawm kev sau reposefully, kev kub ceev, kua theem tswj, capping ntseeg tau, zaus hloov pauv lub sijhawm, cov khoom siv tsawg dua. Nws tuaj yeem nruab qhov kev tswj xyuas qhov ntev. Nws yog cov khoom siv uas nyiam tshaj plaws rau nruab nrab npias thiab dej haus cog.

Lub ntsiab nta:

● Lub kaw lus tus poj ntsuam uas zoo nkauj, meej, yooj yim thiab ua haujlwm heev;

● Cycling tank tsim nrog precision polishing hauv;

● High precision thiab loj txaus tus nqi filling li qub kom ua tau raws li qhov yuav tsum tau ua;

● Cov qauv tsim tshwj xeeb rau cov menyuam yaus uas yooj yim los kho, kaw thiab xyuas kom muaj kev sib khi ua haujlwm;

● Cov phooj ywg thiab yooj yim kev khiav hauj lwm vaj huam sib luag nrog siab expansibility.

● Lub filling valve yog txais yuav siab precision mechanism valve, ceev ceev filling, siab precision kua theem.

● Lub filling vat txais cov khoom siv 304L tsim sealing vat, kom ua tiav qhov siab tas li.

● Tus nqi ntws ntawm lub filling valve> 125ml / s.

● Lub ntsiab kis tau tus mob txais kev siv toothed thiab gearbox qhib hom kis tau tus mob, kev ua haujlwm siab, tsis tshua muaj suab nrov.

● Lub ntsiab tsav adopts kauj ruam-tsawg ceev hloov rau zaus conversion, tag nrho lub tshuab txais PLC tswj; lub tshuab capping thiab filling tshuab txais kev sib txuas ua ke, kom ntseeg tau tias kev sib koom ua ke ntawm ob lub tshuab.

● Nrog filling nrog lub peev xwm, tsis muaj filling yam tsis muaj peev xwm.

● Cov txheej txheem filling yog lub siab tsis tu ncua, nrog kev ua kom nrawm nrawm thiab ua haujlwm ruaj khov.

● Txais yuav qhia rau hauv tag nrho ntawm Switzerland (Ferrum) capping tshuab.

● Capping trolley txais siab hardness alloy steel quench (HRC>62), capping nkhaus adopts projection grinder precision machining, los xyuas kom meej qhov zoo ntawm capping.

● Nrog capping nrog tuaj yeem, tsis muaj capping yam tsis muaj peev xwm tswj tau, kom ntseeg tau tias lub tshuab ua haujlwm zoo li qub.

● Nrog CIP tsis siv neeg rinsing muaj nuj nqi.

● Nrog centralized lubrication system.

Cov txheej txheem ua haujlwm:

Yuav raug thawb mus rau hauv tuaj yeem tuav lub platform ib los ntawm ib qho los ntawm kev noj cov ntsia hlau thiab lub hnub qub-log. Lub khob ntim ntawm lub khob ntim dej yuav poob rau hauv tuaj yeem; qhov kev ncua deb ntawm filling li qub thiab cov kaus poom yog kaw los ntawm springiness yas nplhaib. Lub zog ntawm lub khob nruab nrab yog tsim los ntawm cov yas idler log raws curvilinear motion. Tom qab ua tiav, lub valve yuav raug kaw, cua tawm, thiab lub khob nruab nrab yuav sawv los ntawm lub kaus poom. Sau tau yuav raug xa mus rau conveyor saw, ces mus rau capper. Capper yuav siv lub hau, tig hla lub ntug ntawm lub peev xwm thiab tig ntug kom tiav qhov kev sib khi los ntawm kev tswj cov cam. Tom qab ntawd tuaj yeem hloov mus rau qhov system conveying.

Main Specifications:

1. Cov khoom siv ntawm lub valve: Stainless hlau SUS304

2. Cov khoom siv ntawm cov phaj teb thiab tshuab platform: Stainless hlau SUS304.

Accessories hom

D) Lub tshuab sov

Lub tshuab ua kom tsis muaj menyuam txuas ntxiv no yog tsim tshiab thiab tsim los ntawm kev qhia txog cov txheej txheem txawv teb chaws siab heev. Nws yog siv rau sterilizing kinks ntawm cov khoom noj khoom haus, xws li yas / iav fwj kua txiv thiab npias, tin tau thiab txhuas tau kua txiv nyob rau hauv lub siab zoo tib yam, thiab txawm rau txias lub kub filling tshuaj yej thiab kua txiv hmab txiv ntoo haus thiab ua kom sov qhov kub thiab txias filling carbonated-soft. dej haus.

Lub tshuab no yog sib xyaw ua ke los ntawm cov dej kub txauv, dej sov ua ntej txias, thiab cov kaus poom sov so uas tuaj yeem tau txais dej zoo dua thiab kev txuag hluav taws xob. Tag nrho cov kaus poom yuav nqa mus rau hauv thiab tawm mus, thiab cov kab yuav ua tiav tag nrho. Lub cev tag nrho ntawm lub tshuab yog ua los ntawm 304 stainless hlau; nyob rau hauv tas li ntawd, lub tshuab muaj ib tug zoo tsos, du khiav lub xeev thiab yooj yim ua hauj lwm.

Model: PEB

Khoom siv: SUS304 Stainless hlau

Input: stainless hlau dej flume

Lub twj tso kua mis: 1-25T / H

Tag nrho qhov ntev: 8000m

Luj: Txog 2800kg

E) PE Zaj duab xis Shrink-wrapping Tshuab

Daim ntawv thov:

1. Qauv: LYBS6545auto film wrapping tshuab

LYBS 6545 nws pib zaj duab xis wrapping tshuab yog tsim thiab tsim raws li cov thev naus laus zis tshiab, rau qhov kev thov ntawm kev ntim khoom ntawm cov dej haus, xws li dej ntshiab, dej ntxhia, kua txiv hmab txiv ntoo, dej qab zib, thiab lwm yam. Nws yog tsis siv neeg wrapping, nrog shrink qhov, ntim zoo kawg nkaus.

2. Nta ntawm LYBS 6545 pib zaj duab xis wrapping tshuab

1) Tsis siv neeg sorting conveyor system, uas muaj cov kev taw qhia kev sib cais stainless hlau raj thiab cov phaj sorting ua cov fwj nyob rau hauv txheem yob rau lub hom phiaj qhwv, kom paub tseeb tias cov pab pawg neeg ntawm fwj ntawm 3 x 4, 4 x 6, los yog 2 x 6, 4 x 5 pcs ntawm fwj nyob rau hauv qhov chaw rau wrapping xav tau.

2) Tsis siv neeg PE membrane ua ib feem, uas muaj lub sab sauv thiab qis yob-feed PE membrane system nyob rau hauv qhov chaw thiab nruab nrog tsis siv neeg infra-red sensoring system rau xyuas cov pab pawg neeg ntawm lub raj mis npaj rau wrapping thiab txiav sealing, tag nrho cov txheej txheem yog mus ua tiav tam sim ntawd los ntawm PLC tswj qhov system.

Cov fwj qhwv yuav raug thawb mus rau hauv lub shrinking tunnel conveyor los ntawm lub tshuab tsis siv neeg thawb, uas thawb lub raj qhwv mus rau hauv lub conveyor ntawm lub qhov shrinking.

3) Tsis siv neeg kub cua shrinking qhov, lub shrinking system yog cais ib feem ntawm lub tshuab muaj lub cais tswj chav tsev rau qhov kub thiab txias tswj los ntawm kov screen kub tswj system.

4) Kov npo tswj vaj huam sib luag nrog PLC thiab hluav taws xob tswj qhov system.

F) Lub raj mis ntim Conveyor System

Cov yam ntxwv tseem ceeb:

1. ruaj khov conveying, siv synchronous chasing tswj ntawm lub conveying siv thiab cav, ua lub raj mis nyob rau hauv zoo mob nyob rau hauv lub conveying: tsis poob, tsis-thaiv, tsis jam. Thiab lub cushion platform tuaj yeem teeb tsa ua ntej lub tshuab luam ntawv, thaum daim ntawv hloov pauv, lub tshuab filling tuaj yeem ua haujlwm, tsis tas yuav tsum nres thiab tos. Cov khoom ntim tau ntim rau lub sijhawm no yuav muab khaws cia los ntawm lub cushion, thaum daim ntawv hloov pauv tiav, lub tshuab labeling yuav sau cov khoom khaws cia rau hauv qhov kev kub ceev, thiab ua kom nrawm dua.

2. Kev siv txoj hlua khi yog tsim los ntawm cov qauv, cov khoom siv tuaj yeem hloov pauv tau yooj yim, cov qauv yog compact, suab nrov me ntsis, yooj yim assembling thiab tswj, muaj kev yooj yim los ua ke lub raj mis hom raws li lub peev xwm sib txawv.

3. Kev tsim hluav taws xob tswj tau siab heev thiab tsim nyog, peb tuaj yeem tsim cov txheej txheem tswj, xaiv cov khoom siv hluav taws xob tswj raws li tus neeg siv khoom tsim, txhawm rau txhim kho kev ruaj ntseg conveying.

4. Hloov raws li cov txheej txheem conveying lossis cov neeg siv khoom tsim nyog, kom yooj yim ntawm kev ua haujlwm.

5. Siv lub tshuab lubricating yog nruab

6. Qhov tseem ceeb tag nrho siv SUS304.

7. Fringe board yog siv US Rexnord technology los tsim.

Lub sij hawm xa tuaj: Nov-30-2022